Our Projects

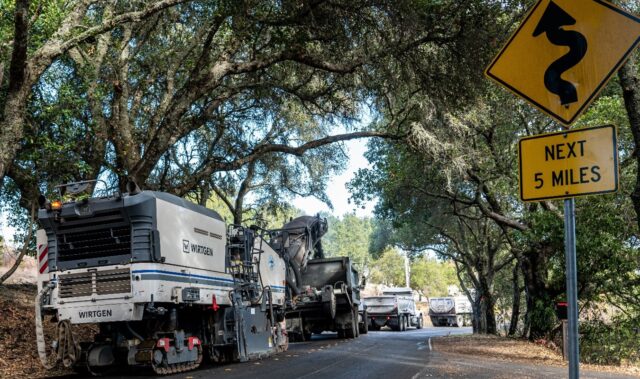

Page Mill Road Reconstruction

Palo Alto, CA

The Page Mill Road Safety Improvements project included the resurfacing and reconstruction of 11 tight switch back turns on the winding and hilly Page Mill Road that connects Palo Alto to the coast. All the construction was to improve the safety of each turn for motorists and the many bicyclists that traverse the pass each day.

PRS partnered with Teichert Construction to complete the 2” milling and overlay in multiple sections within about a 10-day window. Page Mill road, being as narrow as it is and with the tight traffic closure allowances, proved to be a logistical challenge. Jeff M. of PRS Sacramento, operated his Wirtgen 210 cold planer with care and precision through the picturesque hills, while staying out ahead of the paving crew.

“The project was pretty complicated and required me to stay on my toes and the whole team to be hyper-focused on safety. We were working long drop-offs, under the canopy of oak trees and very narrow roadways. There was a lot going on in a small space, but we were able to keep traffic flowing safely,” said Jeff, PRS Operator.

“Your milling operator onsite always stayed ahead of our paving crew and everything went real smooth. From dispatch through the end of the job, PRS helped make this a super easy and smooth project for me,” said Dan Bowen, Teichert Superintendent. PRS and Teichert were able wrap up the project, ahead of schedule and with zero safety incidents, together.

PRS SD & PCC SD – Milling & Fabric Laydown

Friars Road, San Diego, CA

PRS and PCC had the opportunity to work together with a valued and longtime customer. PRS made short work of the milling side of the project on Friars Road under the 5 Freeway with his clean and well-maintained Wirtgen 210. Next, the PCC team went to work applying PG 64-10 hot oil and Trupave fabric setting up the general contractor for successful paving operations. As one company, PRS and PCC were able to provide professional services covering multiple aspects of the same job.

Milling & P3 Smoothness Solutions – 3D Milling, Micro Milling

Rte 52 – San Diego

The scope of this work was to repair massive settling of the roadway causing a danger to the driving public. The cause of the settlement is due to the roadway being built over an area that was once a landfill, resulting in voids under the structure of the road. It was our intent and design, working hand-in-hand with CalTrans, to utilize our P3 applications.

The first phase of this project was to correct extreme roughness to make the roadway safe for traveling public during compaction grouting by utilizing an inertial profiler and LiDAR scanner. The data was used to identify locations requiring deeper cut depths, locations with long wavelengths that the 30’ ski couldn’t correct and any cross slope or draining issues, such as, puddling in lanes. After first phase was completed utilizing the strategy with a micro mill, the roadway improved by 29%. The roadway was then paved in two lifts, first lift of .12’ HMA and second lift of .20’ RHMA. Inertial profile data was collected during paving on both lifts to ensure no corrections to first lift would be needed to meet smoothness on final surface. the smoothness achieved on final surface, large variable cuts, improvements on long wavelengths and corrections to cross slopes could not have been accomplished without the use of PRS provided design model and 3D automated machine control.

Ready?

We're here and we are ready.